AUTOTRANS SYSTEMS

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to AUTOTRANS SYSTEMS

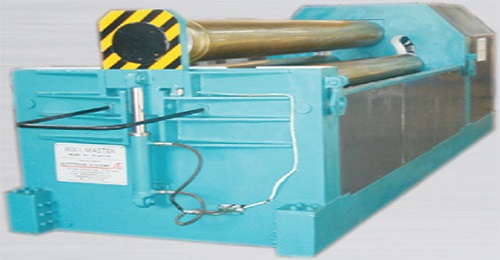

Roll Fixed Axis Plate Bending Machine

As shown the machine is most suitable as a replacement to conventional plate bending machine where pre bending is done manually or on press machine outside and then inserted to machine for rolling purpose. The machine is most economical model among all plate bending machine and is most useful for small fabrication shop as well as the shop having separate press machine on which pre bending can be carried out. Since this is a rolling only machine all the power is available for rolling purpose and one can roll smallest possible diametrer for heavy thickness plate material. The same machine can also used for plate straightening machine for small left over rolled material which is to be reused after straightening. Also rerolling is easily possible in this machine which enables apple effect correction and out of roundness correction to make it a perfect circular shape to component.

Standard Featues

Both the bottom rolls are driven rolls

All rolls are mounted on heavy duly ball bearing .Total 4 bearing per roller

Fully hydraulically operated machine requires less input power compared to electro hydraulic

Separate digital roll position meter for each side of roll makes it easy to maintain parallelism between top and bottom roll

Extra heavy central support with bearing to resist point load on roller and for longer roller life

Hydraulically operated drop end frame for ease of job removal

A single person can operate the machine while rolling

Optional Features

Hardened rolls up to 52-55 RC

Tilt able top roll for ease of removal 0of duly rolled shells

Cone bending arrangement between bottom rolls for smaller diameter cone rolling

Extra heavy cone bending arrangement on frame for bigger diameter cone rolling

Electrical control panel with moving trolley for all around access to operator

PLC controls for automatic bending and rolling

All 3 rolls positively driven for thin material rolling

Extended shaft for section rolling die mounting for rolling of section like angle, channel, beams, flats, pipes, bar etc.

Advantages

Specially developed low cost economical hydraulic systems a perfect machine for small engineering work shop

Since the top roll is moved with hydraulic pressure the rolling defect like ovality,apple effect correcion is easily possible.

Due to more power available by hydraulic systems the cycle can be completed in single pass or with minimum no of passes reducing overall operation timefor rolling.

Variable speed of rolling for slow speed for heavy plate thickness rolling and vise a versa.

Only single person can operate machine after plate feeding and up to rolled shell removal.

Small engineering workshop willing to invest less still automate rolling .

Open type rolling requiring mass production qty.

Can use as a straightening machine for pre formed material for reuse

Can use where different operations like pre bending, rolling, material straightening ,Conical rolling, section rolling need to be carried out in single machine.

Optional Features

Hardened rolls up to 52-55 RC

Tilt able top roll for ease of removal 0of duly rolled shells

Cone bending arrangement between bottom rolls for smaller diameter cone rolling

Extra heavy cone bending arrangement on frame for bigger diameter cone rolling

Electrical control panel with moving trolley for all around access to operator

PLC controls for automatic bending and rolling

All 3 rolls positively driven for thin material rolling

Extended shaft for section rolling die mounting for rolling of section like angle, channel, beams, flats, pipes, bar etc.

Application

Railway: water tank, tankar, coach bogie wall profile bending/rolling Automobile: silencers, fuel tanks, mufflers',

Offshore: drill rings

Storage: silos,tanks,

General engineering: Pressure vessal,boiler, tanks, piping, filter body

th moving: Excavator bucket, road roller drum, mobile compactors

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.